Experience SLD Precision's expertise in precision CNC milling parts. Our state-of-the-art machines and skilled team deliver components with exceptional accuracy. We use advanced techniques and materials for flawless performance. Focus on innovation and customer satisfaction drives continuous improvement in our services.

Cost-effectiveness is key for B2B businesses. SLD Precision's CNC milling parts offer a cost-effective solution without compromising quality. Efficient processes and bulk ordering options keep costs low while delivering high-precision components. Whether you need prototypes or large production runs, SLD Precision provides a solution that meets your needs.

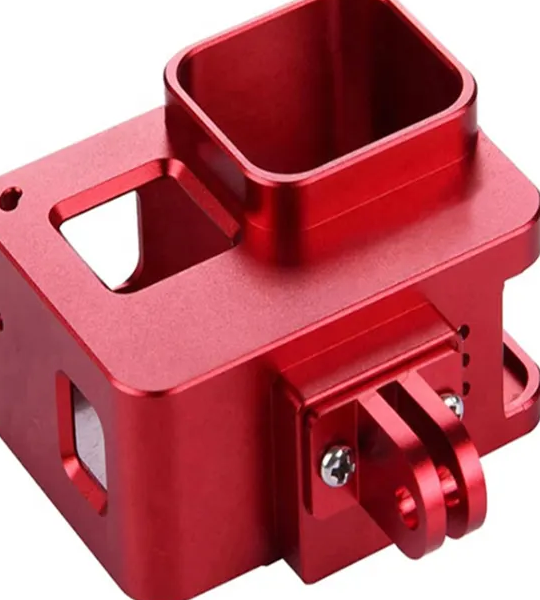

Custom CNC milling parts from SLD Precision offer numerous B2B benefits. They enable precise component creation, enhancing product quality and performance. With various materials and finishes available, parts can be customized to exact specifications. Let SLD Precision help you leverage custom CNC milling parts to drive your manufacturing efforts.

Our commitment to innovation drives us to create advanced CNC milling parts that push the boundaries of precision. We continuously invest in research and development, adopting the latest technologies such as 5 - axis milling and high - speed machining. These advancements enable us to produce parts with unparalleled complexity and accuracy.

By staying at the forefront of industry trends, we can offer you CNC milling parts that are not only suitable for current applications but also future - proof. Whether you’re working on a revolutionary new product or optimizing an existing design, our advanced parts will help you achieve your goals with precision and innovation.

Time is of the essence in manufacturing, and our streamlined production process for CNC milling parts ensures faster turnarounds without sacrificing quality. Our well - organized production lines, equipped with advanced milling machines, enable efficient processing of workpieces. Automated programming and tool - changing systems reduce setup times, accelerating the production cycle.

Moreover, our integrated approach, which includes laser cutting, bending, welding, and assembly services, further optimizes the manufacturing workflow. From raw material to finished part, we handle every step with efficiency, helping you get your products to market quicker and stay ahead of the competition.

Shenzhen SLD Precision Hardware Co.,Ltd was founded in 2018, We are specialized in cnc machining services and Sheet metal fabrication,CNC Parts,CNC Machining,Laser Cutting Service,Injection moldingOur company's advantage is that MOQ is 1 pcs and competitive price and fast delivery, We have YVM, Altitude, Rockwell hardness tester, Caliper, Roughness tester equipment to strictly control the product quality, In order to make sure the critical dimensions, we import our machines from the Germany and Japan. The minimum tolerance we can make is 0.01 millimeter.

Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices. We have already built good business relationships with our customers in the United States, England, France, Germany, Canada, New Zealand, Italy, Hungary, Australia, Poland and Switzerland.

We warmly welcome customers from at home and abroad to establish cooperation and create a bright future with us together.

High-accuracy machining for complex components.

Utilizes cutting-edge CNC machinery for top performance.

Tailored solutions to meet specific customer needs.

Rigorous testing ensures reliability and durability.

Streamlined processes reduce lead times and costs.

SLD Precision manufactures various CNC milling parts, including complex geometries, precision components, and custom parts. We tailor our process to meet your specific requirements.

Yes, we can! SLD Precision has experience with metals, plastics, and composites. Our team advises on the best material for your application.

SLD Precision uses advanced quality control, including CMM inspections and SPC, to ensure parts meet the highest standards.

Lead times vary by project complexity. We strive to deliver quickly without compromising quality.