SLD Precision is your trusted B2B partner for high-speed laser cutting services. With 6kW fiber lasers and automated material handling, we achieve rapid turnaround without compromising precision. Our ISO 9001-certified processes ensure consistency across stainless steel, aluminum, and mild steel projects. Partner with us for scalable laser cutting solutions.

B2B clients partner with SLD Precision for three reasons:

Time is of the essence in today’s fast - paced business world, and our fast - turnaround laser cutting services are designed to meet urgent deadlines. Our streamlined production process, combined with automated laser cutting systems, allows us to process orders quickly without sacrificing precision. Whether it’s a last - minute design change or an emergency restock, we prioritize your urgent projects.

Our responsive customer service team works closely with you to ensure smooth communication and timely delivery. With our fast - turnaround services, you can rely on us to get your laser - cut components to you when you need them most, keeping your production schedules on track.

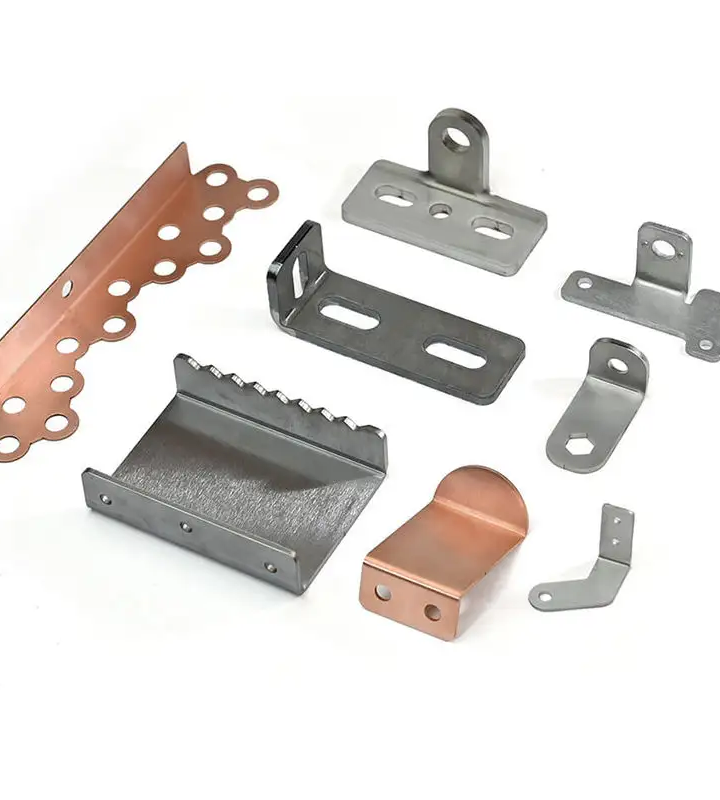

Streamline your manufacturing process with our integrated laser cutting and assembly services. After precision - cutting your components, our experienced assembly team can handle the entire post - processing workflow, including bending, welding, and final product integration. This one - stop approach eliminates the need to coordinate with multiple suppliers, reducing lead times and potential errors.

We use advanced assembly techniques, ensuring secure and reliable connections between laser - cut parts. Whether you need a simple assembly or a complex multi - component product, our comprehensive services provide end - to - end support, giving you peace of mind and a competitive edge in the market.

Every project has distinct requirements, and our custom - tailored laser cutting services are designed to bring your vision to life. From intricate patterns to complex shapes, we have the expertise to handle diverse designs. Our in - house design team collaborates with you to fine - tune your concepts, ensuring that the final cut parts match your exact specifications.

Shenzhen SLD Precision Hardware Co.,Ltd was founded in 2018, We are specialized in cnc machining services and Sheet metal fabrication,CNC Parts,CNC Machining,Laser Cutting Service,Injection moldingOur company's advantage is that MOQ is 1 pcs and competitive price and fast delivery, We have YVM, Altitude, Rockwell hardness tester, Caliper, Roughness tester equipment to strictly control the product quality, In order to make sure the critical dimensions, we import our machines from the Germany and Japan. The minimum tolerance we can make is 0.01 millimeter.

Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices. We have already built good business relationships with our customers in the United States, England, France, Germany, Canada, New Zealand, Italy, Hungary, Australia, Poland and Switzerland.

We warmly welcome customers from at home and abroad to establish cooperation and create a bright future with us together.

High-accuracy machining for complex components.

Utilizes cutting-edge CNC machinery for top performance.

Tailored solutions to meet specific customer needs.

Rigorous testing ensures reliability and durability.

Streamlined processes reduce lead times and costs.

We process mild steel (up to 25mm), stainless steel (up to 20mm), aluminum (up to 15mm), brass, copper, and exotic alloys like Inconel.

We maintain ±0.05mm tolerance with 2D/3D cutting capabilities. Our machines feature automatic focus correction for consistent quality.

Absolutely! We manage prototypes (1-10 pieces) and production runs (10,000+ pieces) with equal efficiency.

We provide welding, powder coating, silk screening, and assembly services to complete your manufacturing project.