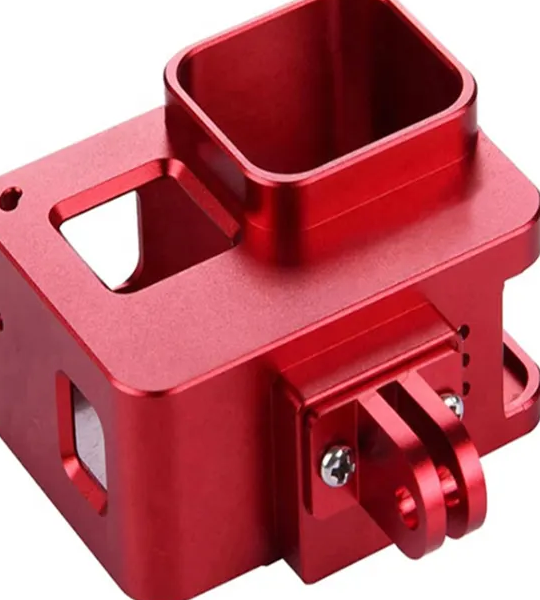

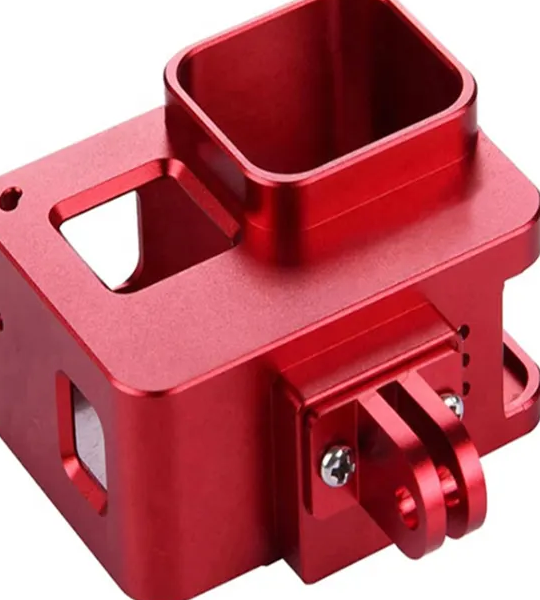

Покращте продуктивність промислового обладнання за допомогою деталей ЧПУ-фрезерування від Точність SLD . Спеціально створені для вимагливих умов, наші деталі забезпечують надійність та ефективність. Можливості налаштування точно відповідають вашим промисловим специфікаціям. Оберіть SLD Precision для CNC фрезеруваних деталей, що підвищують ефективність ваших операцій.

Для застосунків, які вимагають найвищої продуктивності, наші деталі з ЧПУ фрезерування є ідеальним вибором. У важкій техніці наші фрезеровані компоненти можуть витримувати високе навантаження та екстремальні умови, забезпечуючи тривалу міцність. У робототехніці наші точні фрезеровані деталі дозволяють здійснювати гладкі та точні рухи, покращуючи функціональність автоматизованих систем.

Ми використовуємо найновіші інструменти та технології у наших операціях з ЧПУ фрезерування. Це, разом із нашою експертизою у виборі матеріалів, дозволяє нам виробляти деталі, які мають високу міцність, точність та надійність. Коли ви обираєте наші високопродуктивні деталі з ЧПУ фрезерування, ви робите вклад у успіх своїх найбільш вимогливих проектів.

Час має велике значення в виробництві, і наш оптимізований процес виробництва деталей методом CNC фрезерування забезпечує швидші терміни виконання без зменшення якості. Наші добре організовані виробничі лінії, оснащені сучасними фрезерними станками, дозволяють ефективно обробляти заготівлі. Автоматизовані системи програмування та зміни інструментів зменшують час налаштування, прискорюючи цикл виробництва.

Крім того, наш інтегрований підхід, який включає розкрій лазером, гинання, з'єднання сваркою та монтажні послуги, ще більше оптимізує виробничий потік. Від сировини до готової деталі, ми керуємо кожним кроком ефективно, допомагаючи вам швидше вивести продукцію на ринок і залишатися впереди конкурентів.

У B2B виробництві високоякісні деталі для CNC фрезерування є критичними. Точність SLD пропонує найкращі послуги CNC фрезерування, розроблені для клієнтів B2B. Наші сучасні технології забезпечують точні компоненти для авіаційної, автомобільної та медичної галузей. Пridoлігаючись відмінності та задоволеності клієнтів, ми допомагаємо підприємствам покращити свої виробничі процеси за допомогою надійних, високопродуктивних деталей.

Індивідуальні деталі фрезерування CNC від Точність SLD пропонують багато переваг для бізнес-клієнтів. Вони дозволяють створювати точні компоненти, покращуючи якість та продуктивність продукту. З різноманіття матеріалів та покриттів, компоненти можуть бути спроектовані точно за специфікаціями. Дайте SLD Precision допомогти вам використати змістомі CNC фрезерні частини для підтримки ваших виробничих зусиль.

Шенжен Точність SLD Hardware Co.,Ltd була заснована у 2018 році. Ми спеціалізуємося на послугах CNC обробки, виготовленні з листового металу, деталей CNC, CNC обробці, лазерній різці, інжекційному формуванні. Перевага нашої компанії полягає в тому, що мінімальна кількість замовлення становить 1 шт., конкурентоспроможні ціни та швидку доставку. У нас є обладнання YVM, Altitude, твердомір Роквелла, штанген-мікрометр, прилад для вимірювання шorstкості для строгого контролю якості продукції. Щоб забезпечити критичні розміри, ми імпортуємо наші машини з Німеччини та Японії. Мінімальний допуск, який ми можемо досягти, становить 0,01 міліметр.

При триманні бізнес-принципу взаємних вигод, ми здобули надійну репутацію серед наших клієнтів завдяки нашим професійним послугам, якісним продуктам та конкурентоспроможним цінам. Ми вже створили добрі бізнес-відносини з нашими клієнтами в США, Англії, Франції, Німеччині, Канаді, Новій Зеландії, Італії, Угорщині, Австралії, Польщі та Швейцарії.

Щиро вітаємо клієнтів з усіх кутів світу та запрошуємо до співпраці для створення яскравого майбутнього разом з нами.

Висока точність обробки складних деталей.

Використовується сучасне обладнання CNC для найкращої продуктивності.

Особливі розв'язки для задовolenня конкретних потреб клієнтів.

Суворе тестування забезпечує надійність та тривалість.

Оптимізовані процеси зменшують терміни та вартість.

SLD Precision виготовляє різні фрезерні частини CNC, включаючи складні геометрії, точні компоненти та спеціалізовані деталі. Ми адаптуємо наш процес під ваші конкретні вимоги.

Так, ми зможемо! У SLD Precision є досвід роботи з металами, пластиковими та композитними матеріалами. Наша команда радить найкращий матеріал для вашого застосування.

SLD Precision використовує передовий контроль якості, включаючи перевірки КММ та СРК, щоб забезпечити виконання деталей на найвищому рівні.

Терміни поставки залежать від складності проекту. Ми стараємося доставляти швидко, не компроміруючи якість.