Vylepšite svoje výrobné procesy s vlastnou laserovou režou od SLD Precision . Specializujeme sa na zložité geometrie a úzke tolerancie v automobilovej, leteckej a architektonickej oblasti. Náš tím kombinuje modernú technológiu s odbornými B2B znalosťami, aby sme dodali časti, ktoré splňujú vaše presné špecifikácie. Dôverujte spoločnosti SLD Precision pre laserovú režu, ktorá prekoná očakávania.

SLD Precision materiálová expertiza zahŕňa:

Uvedomujeme si dôležitosť nákladovej účinnosti v výrobe a naše laserecké služby ponúkajú ideálnu rovnováhu medzi cenovou dostupnosťou a kvalitou. Optimalizovanými stratégiami reźby a efektívnym využitím materiálov minimalizujeme odpad a znížime výrobné náklady. Naše schopnosti režby v veľkom objeme tiež umožňujú ekonomické výhody mieru, čo sa preloží do úspor pre vaše projekty.

Priechodnými úsporami nákladov nikdy nezanedbávame kvalitu našej práce. Štriktné kontroly kvality, vrátane kontrol v procese a analýz po rezu, zabezpečujú, aby každá časť rezaná laserom dodržiavala najvyššie štandardy. S našimi ekonomickými riešeniami môžete zlepšiť svoju ziskovosť, pričom si zachováte integritu produktu.

Čas je v dnešnom rýchlo sa meniacom obchodnom svete podstatný, a naše služby rýchleho laserového rezu sú navrhnuté tak, aby splnovali naléhavé termíny. Naša optimalizovaná výrobná procedúra, kombinovaná so zaautomatizovanými laserovými rezačkami, nám umožňuje spracovať objednávky rýchlo bez újmy na presnosti. Či už ide o poslednú minútu zmeny dizajnu alebo núdzové doplnenie skladu, prioritne spracovávame vaše naléhavé projekty.

Naše pružné tím zákazníckej slúžby spolupracuje s vami, aby sa zabezpečilo plynulé komunikácie a časový doručenie. S našimi rýchlymi službami môžete počítať, že dostanete svoje laserovo vyrezané komponenty presne vtedy, keď ich najviac potrebujete, čo udrží vaše produkčné plány v poriadku.

V oblasti súčasnej výroby je presnosť nevyjednateľná, a naše služby laserového rezu sú dôkazom excelencie. Pomocou pokročilých laserových technológií dokážeme dosiahnuť rezy s presnosťou na úrovni mikrometrov, čo zabezpečuje, aby každý kus spĺňal najprísnejšie špecifikácie. Či už ide o tenký plech alebo hrubý kompozitný materiál, naše vysokoenergetické lasery režú čistými hranami a s minimálnym tepelným deformovaním.

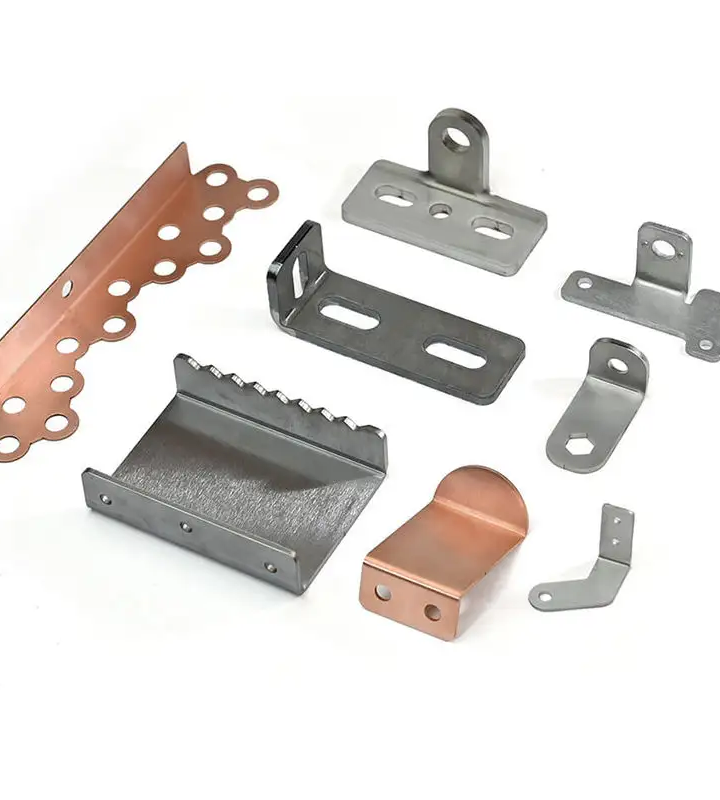

Náš proces laserovej rezu je vysoce univerzálny, schopný spracovať široké spektrum materiálov, vrátane nerdzavého ocele, aluminia a rôznych plastov. S vedením státnou umiestňovanou softvérom pre riadenie rezácich ciest môžeme transformovať zložité dizajny na hmatateľné, vysokojakostné komponenty, čo nás robí vaším ideálnym partnerom pre projekty s dôrazom na presnosť.

Shenzhen SLD Precision Hardware Co.,Ltd bola založená v roku 2018. Specializujeme sa na služby CNC obrábania, plechové konštrukcie, CNC diely, CNC obrábanie, laserové rezanie, iniekčné formovanie. Výhodou našej spoločnosti je MOQ 1 kus a konkurencieschopná cena s rýchlym dodávaním. Máme vybavenie YVM, Altitude, testovač tvrdošťi Rockwell, širokár, testovač hrubosti na striktú kontrolu kvality produktu. Aby sme zabezpečili kritické rozmery, importujeme naše stroje z Nemecka a Japonska. Najmenšiu toleranciu, ktorú môžeme dosiahnuť, je 0,01 milimeter.

Pripadajúc k obchodnému princípu vzájomných výhod, majú sme spoľahlivú reputáciu medzi našimi zákazníkmi kvôli našim profesionálnym službám, kvalitným produktom a konkurencieschopným cenám. Už sme naviazali dobré obchodné väzby s našimi zákazníkmi v Spojených štátoch, Anglicku, Francúzsku, Nemecku, Kanade, Novom Zélande, Taliansku, Maďarsku, Austrálii, Poľsku a Švajčiarsku.

Srdečne vítame domácich aj zahraničných zákazníkov na spoluprácu a tvorbu jasnejších budúcich s nami spolu.

Vysoko presná obrábacia výroba pre zložité komponenty.

Používa moderné CNC stroje pre najvyššiu výkonosť.

Na mieru prispôsobené riešenia zodpovedajúce špecifickým požiadavkám zákazníkov.

Rigidozne testovanie zabezpečuje spolehlivosť a trvanlivosť.

Optimalizované procesy znížia čas dodania a náklady.

Zpracovávame nerez (až 25mm), nerustingujúcu ocel (až 20mm), hliník (až 15mm), mosadlo, miedz a exotické ligatúry ako Inconel.

Udržiavame toleranciu ±0.05mm s možnosťami rezania 2D/3D. Náš stroj disponuje automatickou korrekciou ohniska pre konzistentnú kvalitu.

Absolútne! Spravujeme prototypy (1-10 kusov) a sériovú výrobu (10 000+ kusov) s rovnakou účinnosťou.

Poskytujeme služby svařovania, prachového nátieru, sedliackeho tlačenia a montáže na dokončenie vášho výrobného projektu.