SLD Precision は、高速レーザー加工サービスの信頼できるB2Bパートナーです。6kWファイバーレーザーと自動材料取扱いシステムを用いて、精度を損なうことなく迅速な納期を実現します。当社のISO 9001認証取得のプロセスは、ステンレス鋼、アルミニウム、軟鋼プロジェクトにおいて一貫性を確保します。スケーラブルなレーザーカットソリューションをお求めなら、ぜひ私たちとお付き合いください。

SLD Precision の素材に関する専門知識には以下が含まれます:

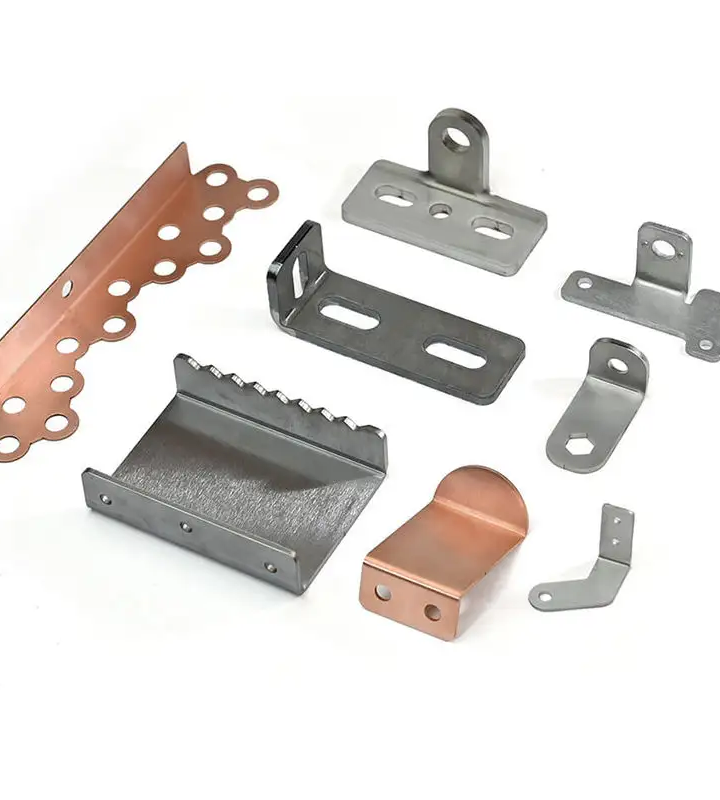

現代の製造業においては、精度が絶対条件であり、当社のレーザーカットサービスは卓越性の証です。最先端のレーザーテクノロジーを駆使し、ミクロン単位の正確さでカットを実現し、すべての部品が最も厳しい仕様を満たすことを確実にします。金属の薄板であろうと厚い複合材料であろうと、高出力レーザーがクリーンなエッジと最小限の熱歪みで切断します。

当社のレーザーカットプロセスは非常に汎用性が高く、ステンレス鋼、アルミニウム、さまざまなプラスチックなど、幅広い素材に対応できます。最先端のソフトウェアによってカットパスがガイドされるため、複雑なデザインを具体的で高品質な部品に変えることができ、精度を重視するプロジェクトにおけるあなたの最適なパートナーとなります。

現代のB2B製造業において、精密レーザー加工はゲームチェンジャーです。 SLD Precision 最先端のファイバーレーザーを駆使し、バリのないエッジと0.05mmまでのマイクロ精度を実現します。自動化されたシステムでは、6m x 2.5mのシートを99%の材料使用率で処理可能です。自動車および航空宇宙分野のお客様には、常に完璧な部品をお届けします。

今日の速いペースのビジネス世界では時間は最重要要素であり、私たちの迅速対応のレーザーカッティングサービスは緊急の納期に対応するように設計されています。効率化された生産プロセスと自動化されたレーザーカッティングシステムにより、精度を損なうことなく注文を迅速に処理できます。最後の瞬間でのデザイン変更や緊急の在庫補充の場合でも、あなたの緊急プロジェクトを最優先にします。

私たちの対応力のあるカスタマーサービスチームは、あなたと密接に協力して、円滑なコミュニケーションとタイムリーな納品を確保します。当社の高速対応サービスにより、最も必要なときにレーザー加工部品をお届けし、あなたの生産スケジュールを維持することができます。

Shenzhen SLD Precision Hardware Co.,Ltdは2018年に設立されました。私たちはCNC加工サービス、板金加工、CNC部品、CNC加工、レーザーカッティングサービス、インジェクション成形に特化しています。当社の強みはMOQが1個からで、競争力のある価格と迅速な納品です。私たちはYVM、アルティチュード、ロックウェル硬度計、カーペンターズルール、粗さ測定器などの設備を備え、製品品質を厳密に管理しています。重要な寸法を確保するために、ドイツと日本からの機械を導入しています。私たちが実現できる最小公差は0.01ミリメートルです。

相互利益のビジネス原則を堅持し,専門的なサービス,品質の良い製品,競争力のある価格によって,顧客に信頼される評判を得ています.我々はすでに米国,イギリス,フランス,ドイツ,カナダ,ニュージーランド,イタリア,ハンガリー,オーストラリア,ポーランド,スイスの顧客と良いビジネス関係を築いています.

国内外のお客様と協力し、共に明るい未来を作り上げることを心よりお待ちしております。

複雑な部品向けの高精度加工。

最先端のCNC機械を使用して最高性能を実現します。

顧客の特定のニーズに応じたソリューション。

厳密なテストにより信頼性和耐久性を確保します。

簡素化されたプロセスによりリードタイムとコストが削減されます。

私たちは、軟鋼(最大25mm)、ステンレス鋼(最大20mm)、アルミニウム(最大15mm)、真鍮、銅、インコネルなどの特殊合金を処理します。

私たちは2D/3Dカッティング機能で±0.05mmの公差を維持しています。機械には一貫した品質のために自動焦点補正機能が搭載されています。

もちろん!プロトタイプ(1-10個)から量産(10,000個以上)まで、同じ効率で対応します。

私たちは溶接、粉体塗装、シルクスクリーン、組立サービスを提供し、あなたの製造プロジェクトを完了させます。