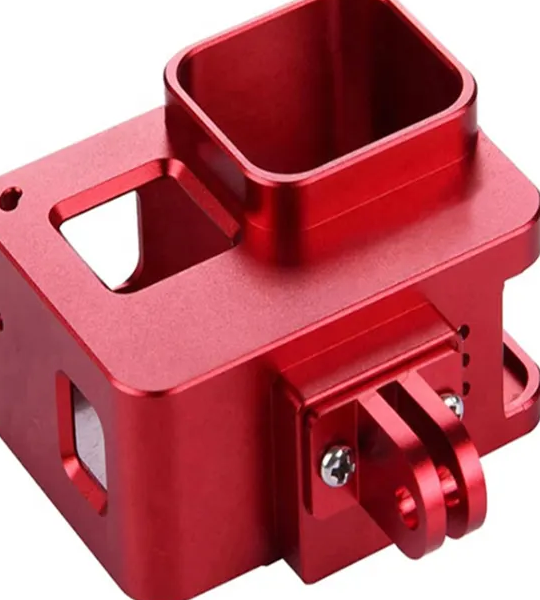

Получитеcustom CNC фрезерные детали, разработанные специально для ваших приложений в Точность sld . Мы предлагаем индивидуальные решения для удовлетворения уникальных требований, от прототипирования до массового производства. Наша команда гарантирует точность и качество каждого компонента. Доверьтесь SLD Precision для всех ваших потребностей вcustom CNC milling деталях.

Изготовление деталей методом ЧПУ фрезерования от Точность sld предлагают множество преимуществ для бизнеса B2B. Они позволяют создавать точные компоненты, повышая качество и производительность продукта. С различными материалами и покрытиями доступна возможность настройки деталей под точные спецификации. Пусть SLD Precision поможет вам использовать индивидуальные фрезерные детали CNC для развития ваших производственных усилий.

Для приложений, которым требуется высочайшая производительность, наши детали для фрезеровки CNC являются идеальным выбором. В тяжелом машиностроении наши обработанные методом фрезерования компоненты могут выдерживать высокие нагрузки и экстремальные условия, обеспечивая длительную прочность. В робототехнике наши точно обработанные детали позволяют выполнять плавные и точные движения, улучшая функциональность автоматизированных систем.

Мы используем самые современные передовые инструменты и технологии в наших операциях фрезерной обработки CNC. Это, в сочетании с нашим опытом в выборе материалов, позволяет нам производить детали, которые обеспечивают превосходную прочность, точность и надежность. Выбирая наши высокопроизводительные детали для фрезерования CNC, вы инвестируете в успех своих самых сложных проектов.

Никакие два проекта не одинаковы, и поэтому наши детали, изготовленные методом CNC фрезеровки, полностью настраиваются под ваши нужды. Мы начинаем с понимания ваших конкретных требований, будь то определенная форма, размер или функциональная особенность. Наша передовая технология CNC фрезеровки позволяет воплотить ваши уникальные дизайны в жизнь. Будь вам нужен единичный прототип или массовое производство индивидуальных деталей, мы готовы помочь.

Во время процесса фрезеровки мы поддерживаем строгий контроль качества на каждом этапе. Это гарантирует, что каждая деталь соответствует вашим точным допускам и ожиданиям по качеству. С нашими индивидуально разработанными деталями, созданными методом CNC фрезеровки, вы можете быть уверены, что ваши продукты будут выделяться своей инновационностью и производительностью.

Точность sld является лучшим выбором для B2B-поставок деталей, обработанных на фрезерных станках с ЧПУ, благодаря нашему стремлению к высокому качеству. От передовых технологий до строгого контроля качества, мы гарантируем, что компоненты соответствуют самым высоким стандартам. Наша команда тесно сотрудничает с вами, чтобы понять ваши требования и обеспечить выдающиеся результаты. Выбирайте SLD Precision для надежных, эффективных и высококачественных фрезерных деталей с ЧПУ.

Шэньчжэнь Точность sld Hardware Co.,Ltd была основана в 2018 году. Мы специализируемся на услугах CNC-обработки и производстве изделий из листового металла, деталей CNC, услугах CNC-обработки, лазерной резки, инжекционного литья. Преимущество нашей компании заключается в минимальном заказе в 1 штук, конкурентоспособной цене и быстрой доставке. У нас есть оборудование YVM, Altitude, твердомер Роквелла, штангенциркуль, прибор для измерения шероховатости для строгого контроля качества продукции. Чтобы обеспечить критические размеры, мы импортируем нашу технику из Германии и Японии. Минимальный допуск, который мы можем обеспечить, составляет 0,01 миллиметр.

Соблюдая деловой принцип взаимной выгоды, мы заслужили надежную репутацию среди наших клиентов благодаря нашим профессиональным услугам, качественным товарам и конкурентоспособным ценам. Мы уже установили хорошие деловые отношения с нашими клиентами в США, Великобритании, Франции, Германии, Канаде, Новой Зеландии, Италии, Венгрии, Австралии, Польше и Швейцарии.

Мы тепло приветствуем клиентов из дома и за рубежом, чтобы установить сотрудничество и создать вместе с нами светлое будущее.

Высокоточная обработка сложных компонентов.

Использует передовое CNC-оборудование для максимальной производительности.

Настроенные решения для удовлетворения конкретных потребностей клиентов.

Строгие испытания гарантируют надежность и долговечность.

Оптимизированные процессы сокращают сроки и затраты.

SLD Precision производит различные фрезерные детали CNC, включая сложные геометрии, высокоточные компоненты и индивидуальные детали. Мы адаптируем наш процесс под ваши конкретные требования.

Да, мы можем! У SLD Precision есть опыт работы с металлами, пластиками и композитами. Наша команда консультирует по выбору лучшего материала для вашего применения.

SLD Precision использует передовой контроль качества, включая проверки на КИП и СПК, чтобы убедиться, что детали соответствуют самым высоким стандартам.

Сроки поставки варьируются в зависимости от сложности проекта. Мы стремимся доставлять быстро, не жертвуя качеством.